EFFECT OF HEAT INSULATION

(THERMAL INSULATION) BOARD

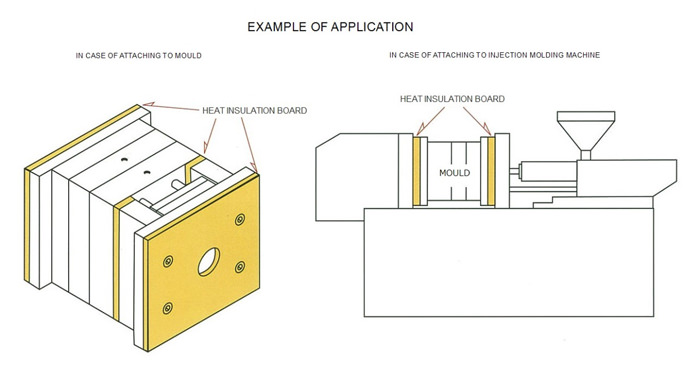

- Since the temperature distribution of a mould(mold) becomes fixed, the quality of products, such as accuracy of dimension and appearance, improves.

- The operating ratio of an injection molding machine improves by shortening the waiting time of a mould(mold) temperature rise.

- By reduction of the heat conduction from a mould(mold) to an injection molding machine, distortion of an injection molding machine decreases and the durability of an injection molding machine improves.

- As the heat dissipation from the die plate (platen) of an injection molding machine is decreased, it becomes energy saving.

OUTLINE OF HEAT INSULATION

(THERMAL INSULATION) BOARD

- Several kinds of heat insulation(thermal insulation) boards from budget-price type to high mechanical strength and high heat resistant type indicated in the table below can be supplied.

- High mechanical strength and can be used as a structural material.

- Since it does not contain asbestos, it can be used as a replacement for asbestos cement board.

- Based on the information of required characteristics, environment, and other applications, the optimum material will be selected.

Swipe horizontally to see the list.

| Units | HIB-A | HIB-B | HIB-C | HIB-D | HIB-E | |

|---|---|---|---|---|---|---|

| Heat Resistant Temperature | ℃ | 250 | 500 | 400 | 200 | 200 |

| Coefficient of Thermal Conductivity | W/m・k | 0.3 | 0.3 | 0.3 | 0.3 | 0.13 |

| Thermal Expansion Rate | 1/℃ | 6.6×10-6 | 9.0×10-6 | 2.3×10-5 | 6.5×10-5 | 28×10-6 |

| Compressive Strength | Mpa | 150~200 | 120~150 | 420~480 | 500~580 | 300 |

| Bending Strength | Mpa | 100~150 | 45~55 | 120~130 | 450~540 | 200 |

| Specific Gravity | 2.2 | 2.2 | 2 | 1.8 | 1.4 | |

| Water Absorption | % | 2~5 | 4~6 | 0.1 | 0.05 | 0.1 |

| Grade | Standard | High Heat Resistant | High Heat Resistant and High Strength | High Strength | High Heat insulation(thermal insulation) |

Swipe horizontally to see the list.

| Units | HIB-F | HIB-G | HIB-H | HIB-I | HIB-J | |

|---|---|---|---|---|---|---|

| Heat Resistant Temperature | ℃ | 550 | 700 | 1000 | 300 | 130 |

| Coefficient of Thermal Conductivity | W/m・k | 0.22 | 0.22 | 0.14 | 0.44 | 0.25 |

| Thermal Expansion Rate | 1/℃ | 9~12×10-6 | 9~12×10-6 | |||

| Compressive Strength | Mpa | 108 | 245~300 | |||

| Bending Strength | Mpa | 130 | 120 | 8.8 | 29.5 | 105~195 |

| Specific Gravity | 2.2 | 2.1 | 0.84 | 1.75 | 1.4 | |

| Water Absorption | % | 0.3 | 0.5 | 3 | 1.3 | |

| Grade | High Heat Resistant | High Heat Resistant | High Heat Resistant | Low Cost | Low Cost |

Swipe horizontally to see the list.

Listed values are measured, it is not a guaranteed value.

Heat resistant temperature is for reference only, and varies depending on the operating conditions.

DIMENSIONS OF BLANK MATERIAL OF HEAT INSULATION(THERMAL INSULATION) BOARD

- Thickness : 0.1~100mm

- Length × Width : 900×1200 mm, 1000×1000 mm, 1000×2000 mm, etc.

Dimensions (thickness, length, width) of the heat insulation(thermal insulation) board are different for each material.

DELIVERY FORM OF HEAT INSULATION

(THERMAL INSULATION) BOARD

Please choose from among the following three types of the delivery form of heat insulation(thermal insulation) board.

- 1. FINISHED PRODUCT

- Finished product after machining such as cutting, grinding and drilling based on your drawing will be supplied.

- 2. BOARD CUT TO SPECIFIED DIMENSIONS

- Board without machining such as drilling, etc. and in the form of simply cutting the material according to the specified dimensions will be supplied.

- 3. BLANK MATERIAL

- Blank material without any machining will be supplied.

MINIMUM ORDER QUANTITY

1 Piece

DELIVERY TIME

After order confirmation, will be shipped from our factory within 1 to 10 weeks(depends on quantity of order)

PACKAGING DETAILS

Standard protective packaging such as cardboard boxes or wooden crates.

WORK FLOW FROM INQUIRY TO SHIPPING

- Inquiry

- Estimate (if necessary, selection of material properties)

- Order placement and payment

- Confirmation of payment

- Production

- Inspection

- Shipping